tags:

Grip Equipment

Gear Review

Innovation doesn’t hit the grip world very often, but when it does, it changes everything. For decades, we’ve relied on the same heavy hitters for large-scale film rigging: 12" and 20.5" box truss. Box truss has been the backbone of our biggest builds - stage rigs, telehandler frames, giant softboxes, crane-flown overheads, process trailer rigs, and more. If you needed strength, span, and repeatable structure, box truss was king. And it stayed king for a very long time… until the first real challenger stepped onto the stage.

Around 2013, modular truss started creeping into the industry - half the size, surprisingly strong for the footprint, and immediately appealing to grips willing to experiment. But the early version of modular truss came with a tradeoff. It needed reinforcement washers and plates, which meant slower setup times and extra complexity. You gained portability and small-format adaptability, but you paid for it in speed and efficiency.

Then 2019 changed the game.

That’s when Modulus-X® hit the market - and it wasn’t a small iteration. It was a rethink. A one-piece 6061 aluminum extrusion with precision-welded end caps. No folded walls. No welded lengths. No reinforcement plates. Just raw strength and effortless speed. Modulus-X took everything good about modular truss and eliminated the friction points. Setup became faster. Rigs became cleaner. The workflow just clicked - fewer parts to manage, easier connections, and more strength.

This system didn’t just add a new tool - it expanded what rigging could look like at all.

Modulus-X truss is strong, light, efficient, and insanely adaptable. It builds quickly. It rigs cleaner. It fits into places box truss could never go. And over the last few years, it’s become a quiet workhorse on stages, process trailers, rooftops, and nearly every kind of specialized rig the modern grip department is asked to create.

So let’s break it all down - from fundamentals to real-world film use-cases:

What is Modulus-X Truss?

What are the different sizes?

What are the load ratings?

Rigging methods

Applications in the film industry

Accessories

20x20 Modulus-X telehandler frame

What is Modulus-X Truss?

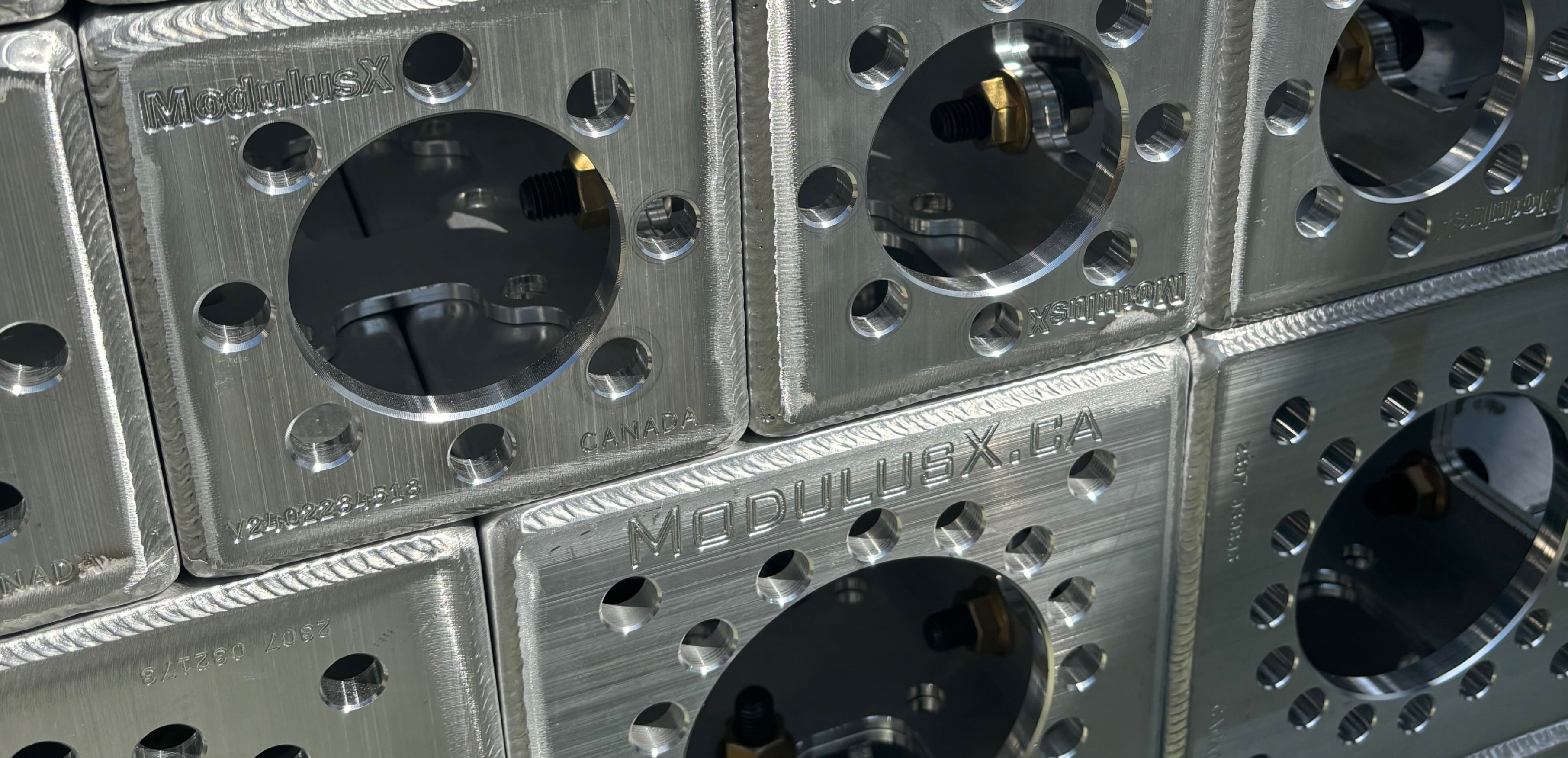

Modulus-X is a next-generation modular truss system built from 6061-T6 extruded aluminum. It’s not folded folded and welded - ModX trusses are single-piece extrusions with precision-welded end caps. The whole system is engineered rather than assembled, and that’s why it’s become one of the highest weight-to-strength truss options in the industry.

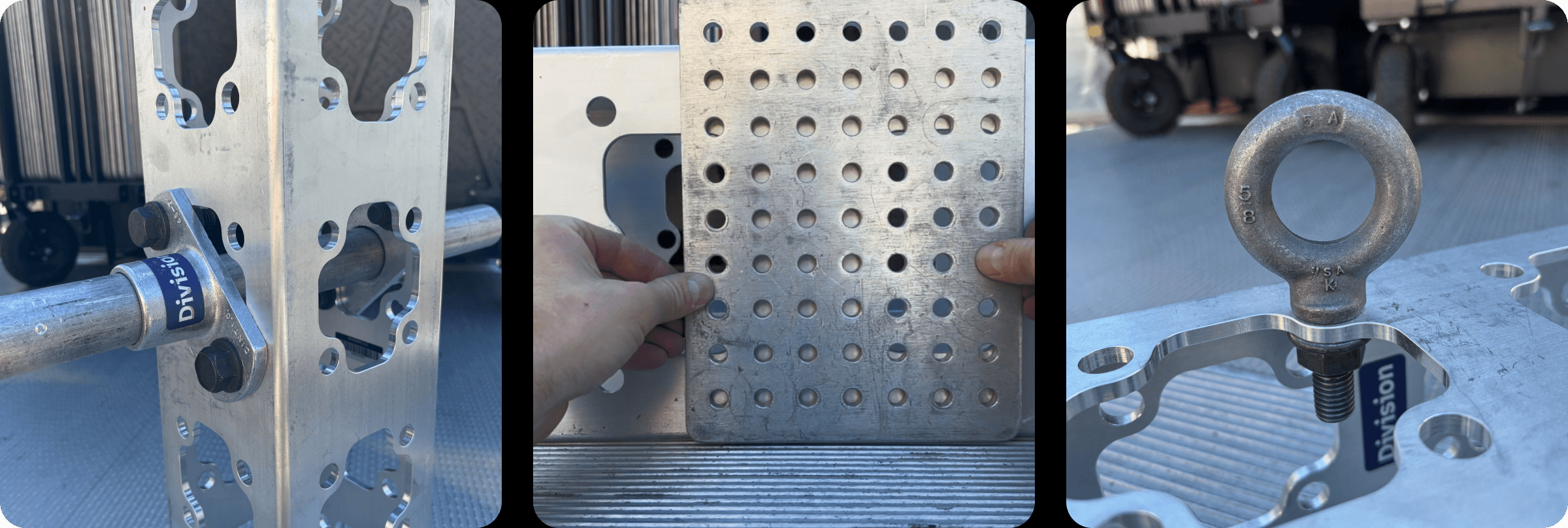

Visually, Modulus-X truss looks similar at first glance to other modular truss. You have hand holes for accessing bolts or nuts on the interior, you have connection points every 3” along each face on all 4 sides, and you have end caps. And this is really where any similarities end. Modulus-X end caps have a radial pattern. This is one of the distinguishing features. This off-axis bolt pattern allows you to rotate the truss at the end caps on both 6” & 9” at different degree increments for each.

On the manufacturer side, Modulus-X is described as “computer engineered, precision-machined, and built using advanced manufacturing principles” - and that shows up in the details. The end caps sit inset into the extrusion, giving you cleaner transitions and drastically improving the shear strength at the connection points. The bolt pattern is off-axis, not straight-through like traditional modular truss, which increases the shear path and lets the system achieve its rated loads without reinforcement plates.

In practical grip language:

it’s lighter, stronger, cleaner to build, and faster to work with. Now who doesn’t want that?

According to Modulus-X, the system is roughly 30% lighter and 50% faster to erect than comparable truss structures, and the bolt layout allows connection points every 3 inches (MX|99 gives you 22.5° increments; MX|66 gives you 45°). On set, that translates to easier mounting options, faster problem-solving, and less fighting the hardware to make something line up.

And unlike earlier modular truss systems, Modulus-X doesn’t need washer plates or reinforcement accessories to reach full strength. Flange bolts and nuts are the only requirement for all standard assembly. You pull this truss out of the truck and it’s ready to go. Only laminating pieces together could make it stronger - something you can’t even do with box truss. That’s why so many grips have adopted it for everything from softboxes and stage pick points to telehandler frames and car rigs.

You get box-truss-level rigidity (and more) in a package that’s more workable.

What are the different sizes?

Speed and strength are only two of the advantages. You know the freelancer saying: “Good, fast, cheap - pick two”?

With Modulus-X, you get speed, strength, and size.

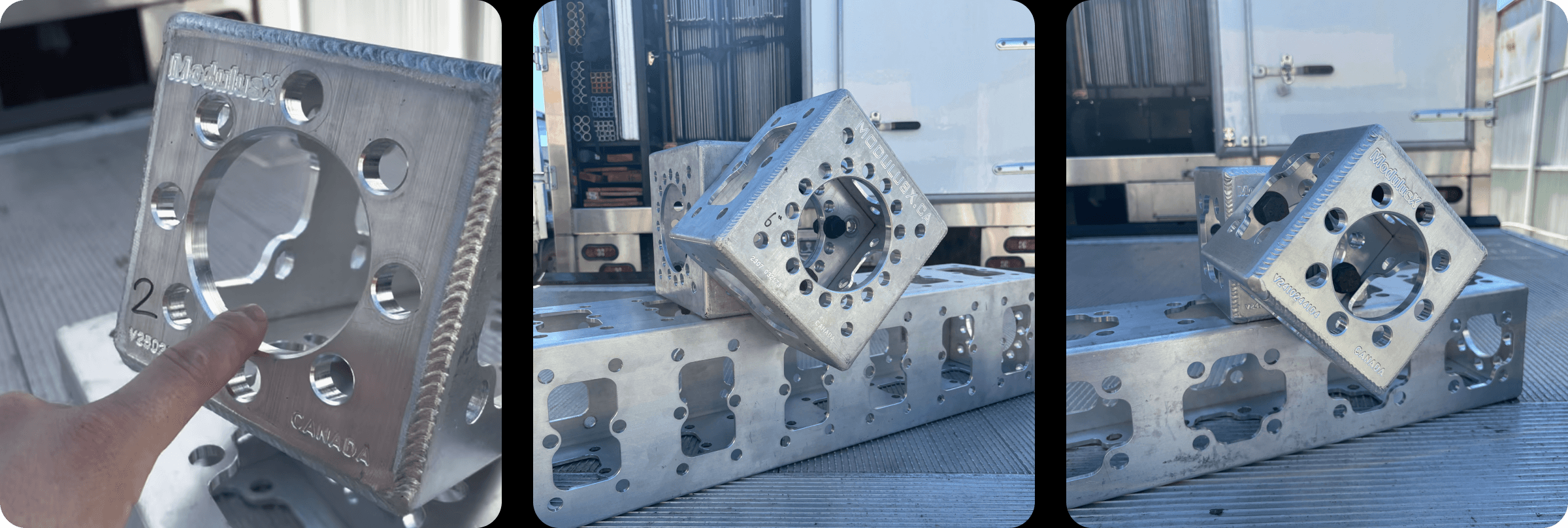

ModX comes in two main sizes:

The 6” size is the perfect truck-friendly format for camera rigs, car rigs, pick points on stage, smaller structural builds, and much more. It's light, manageable, and takes up a quarter of the space of a 12” box truss piece. Plenty of 1st unit keys carry 6” ModX on their trucks now - it solves too many problems not to.

The 9” size felt odd to me at first, but its strength-to-size ratio beats most 12” box truss and blows away other modular truss options. The load charts are wild. More on that below.

You can get both 6” & 9” sizes in the common lengths:

6”, 1’, 2’, 3’, 4’, 5’, 6’, 7’, 8’, 9’, 10’

And the 9” line adds:

9” cubes

18” lengths

Both sizes are designed to complement each other - not compete with each other. The 6” line gives you agility and footprint efficiency for camera, car, and stage builds, while the 9” line steps in when you need longer spans, higher load ratings, or more rigidity under dynamic loads. Together, they cover almost everything a modern grip department needs without jumping up to full-size box truss or compromising on adaptability.

What are the load ratings?

I didn’t pay much attention in high school math, but let me tell you, numbers matter to me now. I wish I listened more back then because load charts are where Modulus-X really flexes.

Mx|99| (9” × 9”)

These are uniform and center-point loads from FEA simulations and live testing. According to the manufacturer:

Span (ft) | Center Load (lbs) | Deflection (inches) |

|---|---|---|

5 ft | 15,250 lbs | 0.22″ |

10 ft | 14,500 lbs | 0.52″ |

15 ft | 10,750 lbs | 1.24″ |

20 ft | 8,000 lbs | 2.09″ |

25 ft | 6,250 lbs | 3.21” |

30 ft | 5,500 lbs | 4.77″ |

35 ft | 4,500 lbs | 6.22” |

40 ft | 3,500 lbs | 8.06” |

Mx|66| (6” × 6”)

Span (ft) | Center Load (lbs) | Deflection (inches) |

|---|---|---|

5 ft | 6,600 lbs | 0.14″ |

10 ft | 4,600 lbs | 0.56″ |

15 ft | 3,200 lbs | 1.28″ |

20 ft | 2,400 lbs | 2.24″ |

25 ft | 2,000 lbs | 3.64” |

30 ft | 1,700 lbs | 5.34” |

Numbers compared to traditional 12" box truss

Here is the part that surprises most grips.

The Mx|99| load ratings blow 12” box truss out of the water when compared with the same spans. It does this in a form factor that is smaller, lighter, easier to handle, and significantly faster to build.

The Mx|66| surprisingly doesn’t fall far behind 12” box truss load ratings. It’s designed for the everyday structural work where box truss is just too much. It gives you strength, precise adjustability, and versatility in a compact format that grips can actually keep on the truck all the time.

Modulus-X did not build these sizes to replace everything on set. They built them to handle the majority of modern grip rigs with more efficiency and better workflow than traditional options.

What this means for grips

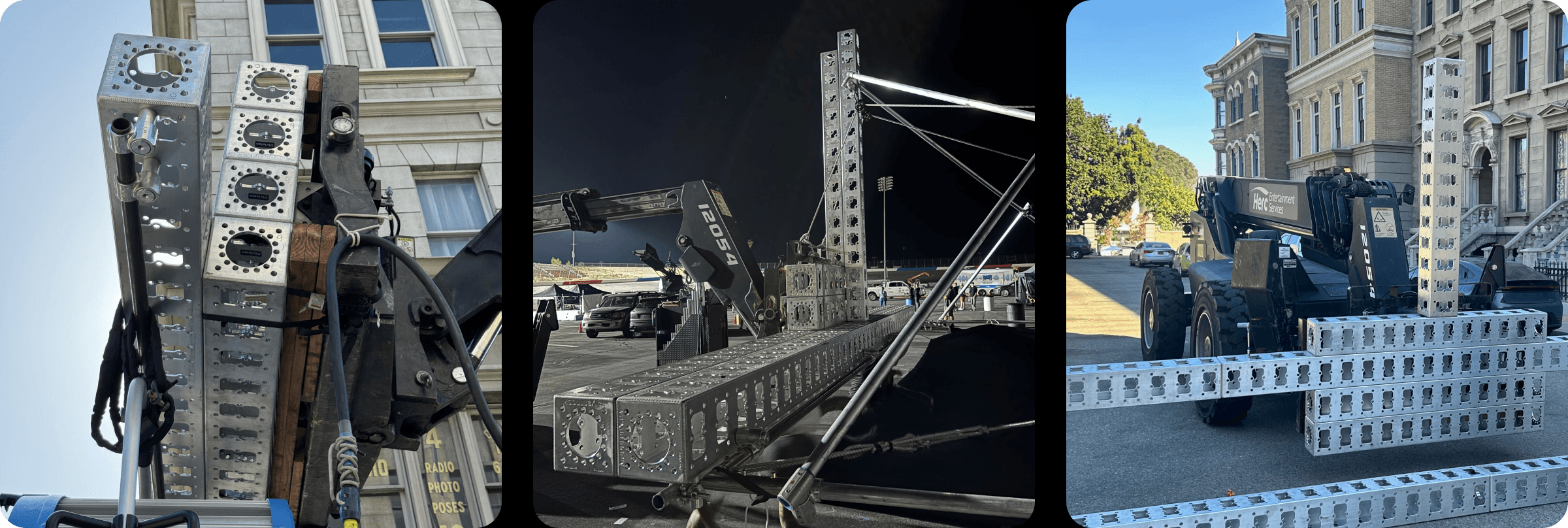

The Mx|99| handles serious spans and structural loads. Rooftop rigs, telehandler frame backbones, platforms, massive softboxes, tents, video walls, and engineered structures are all ideal applications.

The Mx|66| is a true workhorse. Camera rigs, set pieces, small structural builds, stage points, track leveling, and telehandler frames all benefit from its strength and modularity.

Deflection is where ModX really shines. At 15 feet, the Mx|99| deflects only 1.24” inches under more than ten thousand pounds. That level of rigidity keeps your geometry consistent under load.

These ratings are the published manufacturer values. Real-world safe working loads depend on how the rig is built and supported, and whether you’re working with static or dynamic loads, but ModX gives you an extremely solid engineering foundation to start from.

Legacy Grip Takeaway

The Mx|99| operates in the load-rating territory grips traditionally relied on 12 inch box truss for, yet it is lighter, faster to rig, more adaptable, and far more precise in how it connects and builds. The Mx|66| fills the everyday structural needs on set without the bulk and footprint of full-size truss. It’s way stronger than speedrail but way lighter and smaller than 12” box. Modulus-X gives you modern truss engineering in a format built for real-world film work. Always build with limits, but know that this system gives you strength and efficiency that older truss formats simply cannot match.

Rigging methods

Modulus-X changes how you approach a build. Everything about the system is designed to go together quickly and line up cleanly - the off-axis end caps, the 3" on-center pattern, the chamfered hand holes, and the one-wrench workflow. It takes the guesswork out of structural rigging and lets you focus on the geometry of the build instead of fighting hardware. Here are the core rigging methods grips use with ModX on set:

1. Standard Assembly

Everything goes together using flange bolts and nuts.

No washer plates, no reinforcement hardware, no special tools.

Only one 15/16” socket wrench is needed for assembly and disassembly (whereas with box truss you need one on either side for both the nut & the bolt)

2. Off-Axis Rotation (22.5° / 45°)

The radial end-cap pattern is what separates ModX from traditional modular truss.

Mx|99| rotates every 22.5°

Mx|66| rotates every 45°

This allows clean geometry for:

Truss bracing

Custom structures

Custom lighting rigs

Creative problem-solving

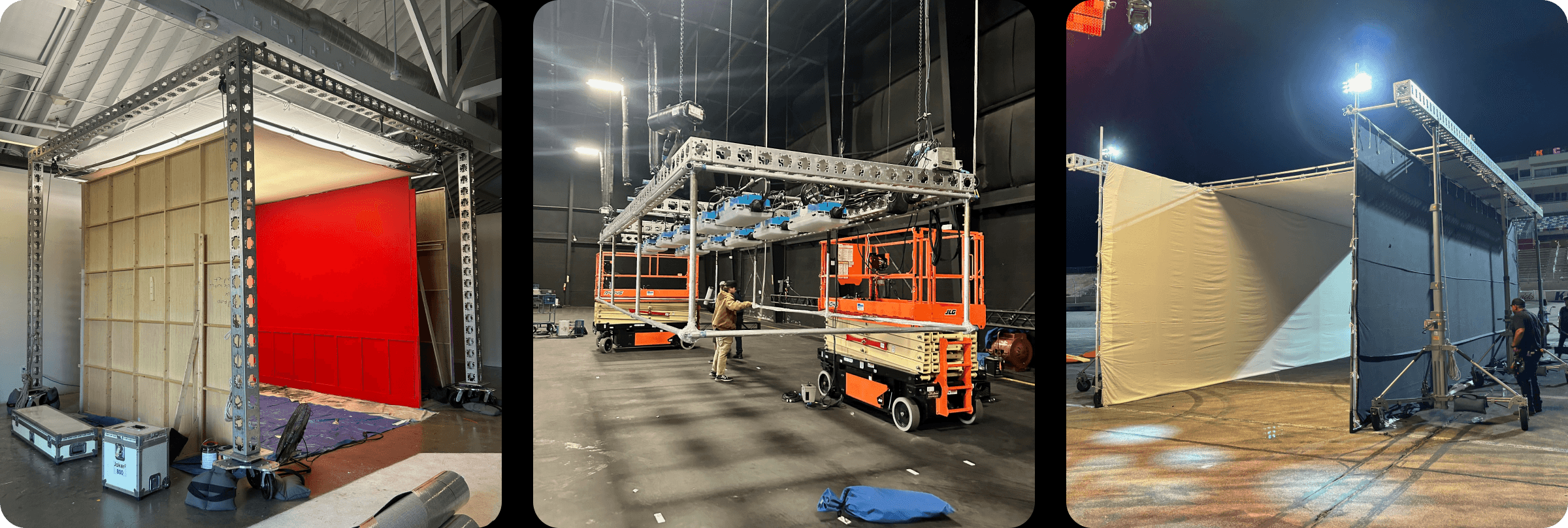

3. Orientation Choices

ModX can be built:

Flat (spans, goalposts, softboxes, overhead telehandler frames)

Vertical (walls, towers, VFX frames)

Because each face of the extrusion is identical, ModX behaves predictably in any orientation - something box truss can’t claim. With ModX truss orientation doesn’t matter.

4. Laminating for Strength

One of the biggest advantages ModX has over box truss is laminating.

You can bolt two or more pieces together - side-by-side or stacked on top of one another - to dramatically reduce deflection and increase load capacity.

No welding, no custom fabrication - just additional truss pieces and bolts.

This is standard practice for:

Telehandler frame attachment

Large structures & platforms

Live event rigging

LED wall support structures

5. Hybrid Building

ModX integrates cleanly with traditional grip hardware:

Speedrail starters

Cheeseplates (3” spacing lines up perfectly)

Cribbing / wood

Mitchell mounts

Hollaender flanges

Motors and steel via eye bolts or rigging plates

It’s built to play well with everything you already use on set. More on accessories and adaptability in a bit.

Legacy Grip Takeaway

Modulus-X rigs the way grips want to work: fast, predictable, modular, and strong.

You can rotate it, laminate it, run pipe through it, bolt wood to it, hang motors off it - whatever the build calls for. The system gives you the structure, and you supply the creativity.

Applications in the film industry

Modulus-X was designed for versatility, and nowhere is that more obvious than on set. Whether you are on first unit, deep in a rigging day, or engineering specialty camera moves, this truss system adapts fast. The strength-to-size ratio, the connection points, and the off-axis bolt patterns all open the door for builds that are cleaner, lighter, and much faster to execute compared to traditional hardware.

Here’s how ModX shows up across the three major areas of film production.

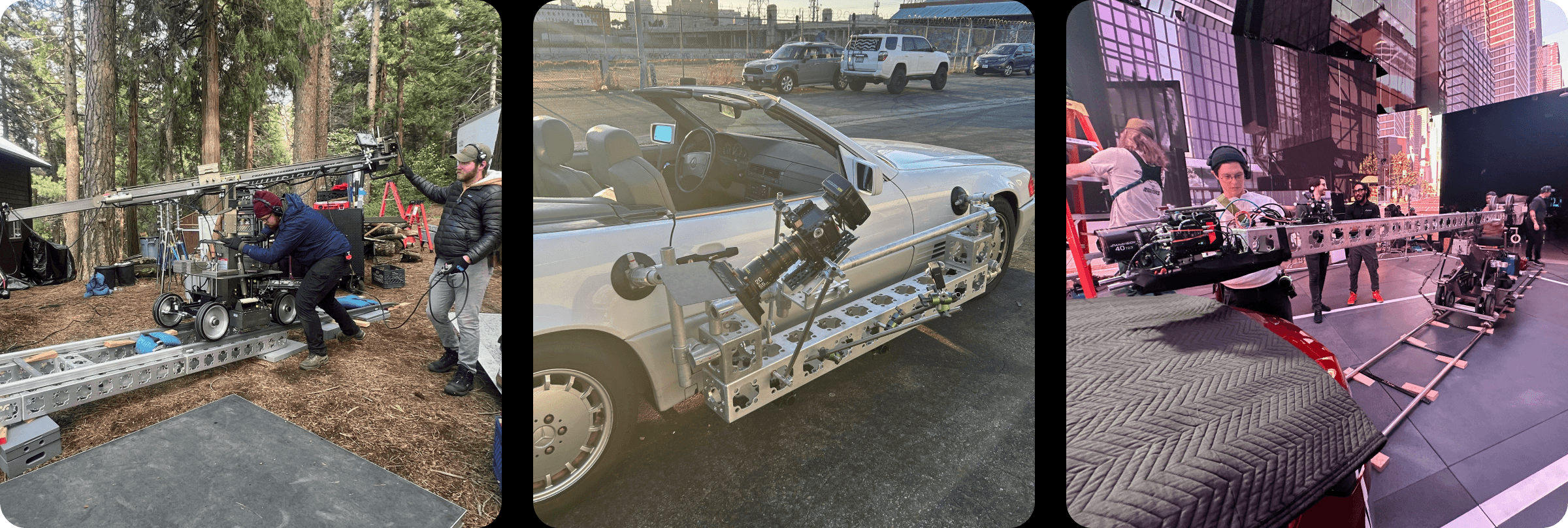

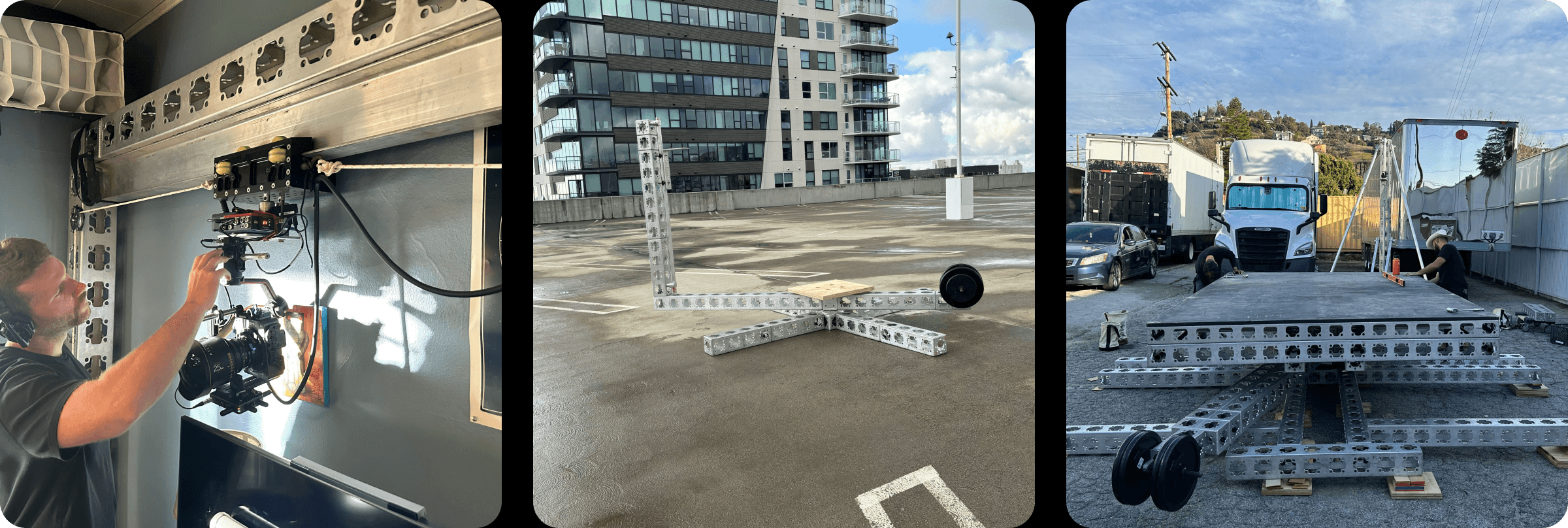

1. First Unit

First unit days demand speed, repeatability, and efficiency. You rarely have the luxury of long prep or custom fabrication. ModX excels here because it lets you build structural, reliable rigs on the fly without dragging around full-size box truss.

Typical First Unit Uses:

Camera offsets

Dolly track leveling

Camera positions

Vehicle mounts

Goal posts

Why it works:

Fast assembly with easy access holes for speed

Small footprint (but strong) for working in real locations

Small enough to carry in the 1st unit trailer

ModX gives first unit grips the ability to problem-solve without slowing down the production or waiting on big gear.

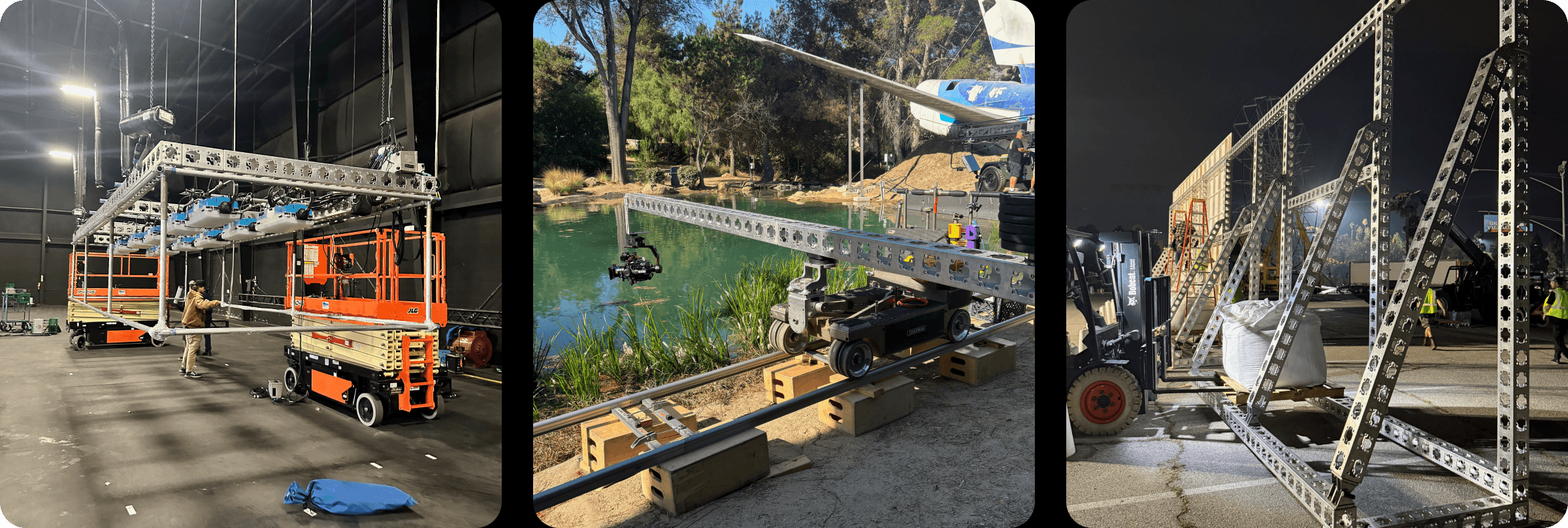

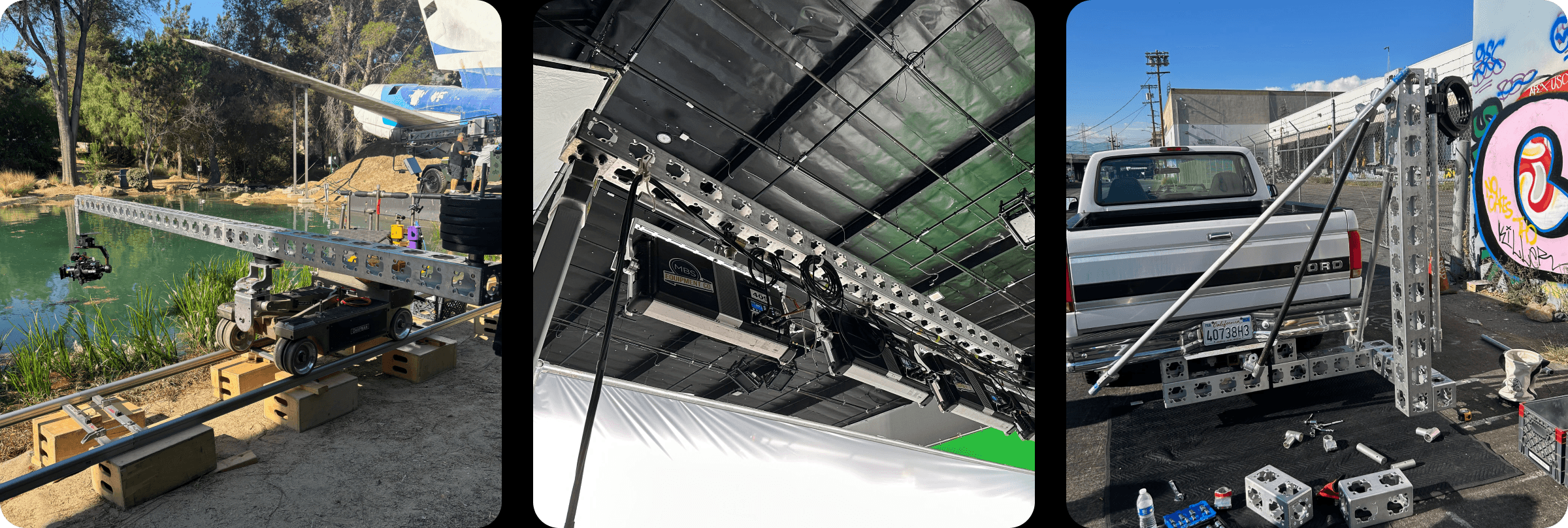

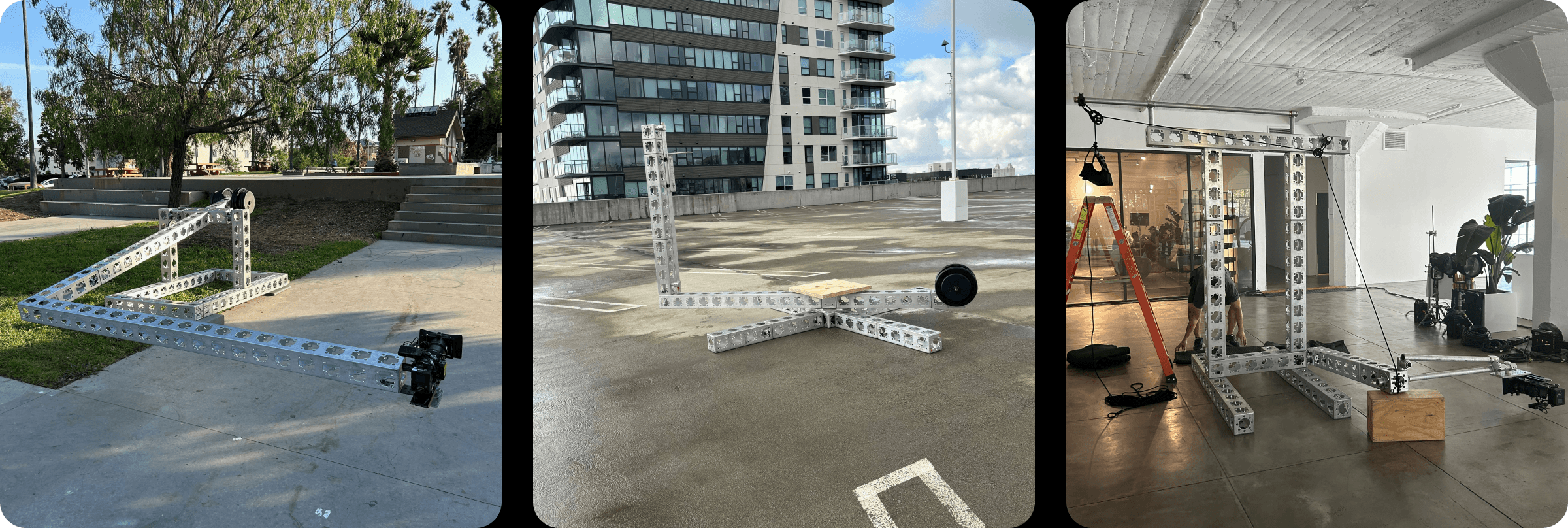

2. Rigging

Rigging is where ModX truly becomes a force multiplier. The Mx|99| offers load ratings and deflection numbers that rival what grips typically expect from 12 inch box truss, but in a smaller and lighter format. This lets rigging crews pre-build structures faster, move them more efficiently, and fly frames with less hardware. That’s a win win win, if I can count correctly.

Common Rigging Grip Builds:

Softboxes

Tents

Telehandler frames

Crane-flown overhead frames

Rooftop overhangs and structural spans

Dead hang points on stage

LED walls

Platforms

Why riggers like it:

Only flange bolts needed for assembly

1 wrench needed for tightening or loosening bolts

Lighter to lift, suspend, or move around stage

Easier to transport - takes up 1/4 of the space as 12” box truss

Strong enough for demanding spans

Laminating pieces gives you extra strength and less deflection

Modular and easy to adapt to

Modulus-X gives rigging crews structure without bulk. That means safer builds, faster load-in, and a cleaner look. Who says grips don’t care about vanity?

3. Camera Movement

Camera movement is one of the most creative and engineering-heavy parts of grip work. ModX supports that creativity by offering a rigid, precision-friendly platform that you can adapt to countless specialty moves.

Camera Movement Use Cases:

Rainbow rigs

Lazy susan rigs

Overhead 360s

Rotissery Rigs

Custom rigs

Why it matters:

ModX is rigid

The 22.5-degree (Mx|99|) and 45-degree (Mx|66|) end cap radial patterns let you integrate ModX at angles if needed

A variety of 3rd party components exist that adapt to ModX and make it more useful

Plenty of mounting options

3” on center holes align perfectly with cheeseplates

Camera departments love stability. The camera nerds love their assurances. And ModX brings that in a compact and highly adaptable form.

Accessories & Adaptability

Connecting and adapting to Modulus-X truss is easy - the 3” on-center bolt holes give tons of versatility. Adapting pipe is straightforward, hanging truss is a breeze and a variety of mounting options exist for various other applications. 3rd party attachments have become ubiquitous - here are some ways we adapt to Modulus-X truss.

Pipe & Speedrail

Plates & Rigging Hardware

Fork adaptors

Camera Mounting

Female & male mitchell adaptors

Euro clamp & Euro adaptor

Bearings, Movement & Counterweight

Dolly rotators

Lazy susan bearings

Counterweight brackets

Truss slider

Truss trolleys

Connection Plates

Straight plates

30 degree angle plates

Leveling & Rolling

Legacy Grip Takeaway

Modulus-X isn’t just a truss - it’s a complete platform.

It works seamlessly with pipe, wood, cheeseplates, rigging hardware, Mitchell heads, and all the materials grips already rely on. The system is adaptable by design, which means it doesn’t force you into its workflow - it opens yours up more.

Wrap Up

Modulus-X didn’t break into the grip world because it was shiny, new, or different - although grips do get excited when that’s the case. It earned its place because it solved real problems that grips have been fighting for decades. Some grips have been slow to adopt and others have seen the advantages immediately and never looked back. Traditional box truss gave us strength but demanded space, weight, and time. Early modular truss gave us portability but cost us speed and versatility. ModX is the first system to bridge that gap: the strength of structural truss without the size limitations, and the workflow speed that modern productions demand.

What makes Modulus-X special isn’t just the engineering - though the single-piece extrusion, off-axis end caps, and 3" bolt holes are a big part of the story. It’s the way those details translate directly to real grip work. You can build a softbox faster. You can span a 30’ distance on a goalpost when you couldn’t with speedrail. You can laminate sections for insane rigidity. You can mount truss at angles. You can integrate speedrail, wood, cheeseplates, bearings, Mitchell mounts, motors, and other hardware without complication. Adaptation is 1 step away - and the 3rd party components are bountiful. ModX is structural, it’s clean, it’s efficient, and it plays well with the tools grips already rely on.

For the grips who want their builds smarter, faster, lighter, and cleaner, Modulus-X is the tool we’ve been waiting for. It expands what’s possible on set and gives the modern grip department a structural system that finally matches the creativity and problem-solving the craft demands. And we’re only scratching the surface of what it can do. As with anything in gripping we want the limit to be our imagination. Not the tool.

BONUS: Top Tips & Workflows for Modulus-X

ModX has chamfered edges around the utility holes - way easier on your hands when you’re working inside the truss.

The truss end caps fit Mitchell heads and tie-downs. No need for special adaptors.

You only need one wrench - the flanges keep the nuts and bolts from spinning when tightening or loosening.

Hollaender floor flanges let you pass speedrail through the truss for a super low-profile build. Great for space saving.

You can connect ModX at angles with the end caps - Mx|66| every 45°, Mx|99| every 22.5°.

You can even integrate 2x4s straight into the ModX - perfect for platforms or set builds.

No washer plates needed for strengthening connection points - the flange bolts and truss design do the heavy lifting.

Need to center a pipe? Short barrel crosses lined up on one side of the truss will offset the pipe to the center.

Long screw bit + fender washers are a quick way to attach cribbing or lumber to ModX.

Cheese plates line up naturally - they’re 1" on center and ModX is 3" on center.

by:

Legacy Grip